Our engineering teams can define the qualification strategy for your equipment.

- Definition of the industrial production diagram

- Drafting of the qualification plan

- Drafting of inspection specifications

- Definition and design of test equipment (monitoring)

- Laboratory monitoring of testing

- Reports analysis

- Drafting of Qualification Synthesis Report (QSR)

- Drafting of the RTF

- Qualification maintenance

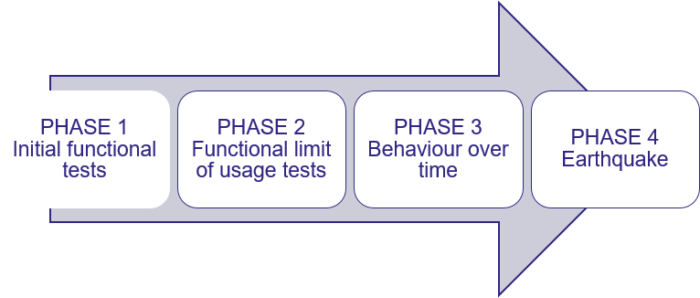

Qualifications include several phases:

PHASE 1

Initial tests

- Visual and mechanical inspections

- Inspections of the degrees of protection provided by the housings

- Dielectric strength at 50 Hz

- Insulation resistance

- Dielectric strength

- Consumption

- Overload and short-circuit withstand capacity

- Electrical continuity of mechanical earthing

Functional tests

- Functional validation test

- Reduced functional characteristics

PHASE 3

Assessment of behaviour over time

- Board connection/disconnection

- Mechanical vibrations

- Rapid temperature fluctuations

- Dry heat

- Damp heat

- Cold

- Extended operation

PHASE 2

Functional limit of usage tests

- Influence of ambient temperature

- Influence of humidity

- Influence of the supply voltage

- Influence of a dampened oscillating wave

- Influence of fast transient bursts

- Influence of electromagnetic radiation

- Influence of electrostatic discharges

- Influence of conducted radio disturbances

- Influence of the magnetic field

- Influence of high energy voltage surges

PHASE 4

Earthquakes

Bi-axial accelerogram test

We use a network of partner laboratories to conduct these tests with optimum turnaround times.

We conduct half a dozen qualifications every year.